Chemical Reactor

- Home

- Chemical Reactor

Our product range includes a wide range of ss high pressure chemical reactor, ss316 chemical reactor, mild steel reactors, chemical jacketed reactor, stainless steel reactors and ss reactor 316 for chemical plant.

| Storage Capacity | 2 KL |

| Material Grade | SS304 |

| Material | Stainless Steel |

| Voltage | 220-380V |

| Frequency | 50-60 Hz |

| Surface Finish | Polished |

| Power Source | Electric |

| Motor Power | 10 HP |

| Phase | 3 Phase |

Price Range:-

- Rs 2 Lakh to 50 Lakh Established in the year of 2004, Prakash Industries are the leading Manufacturer And Exporter of an extensive array of Industrial Mixer, Grease Plant, Chemical Reactor, Blending Machine And Plant, Reaction Vessel, Storage Vessel Tank, Resin Plant, SS And MS Pilot Machine,Automatic PVA Emulsion Plant, etc.

We offer premium quality 316 SS Chemical Reactor that are chiefly used in chemical industry. We make these reactors available in various designs that include electric, hot oil and steam heated. Our proficient engineers design reactors in such a way that maximizes net present value for the desired reaction.

Price Range:-

- Rs 2 Lakh to 50 Lakh

| Storage Capacity | 3 KL |  |

| Material Grade | SS316 | |

| Material | Stainless Steel | |

| Voltage | 220-380V | |

| Frequency | 50-60 Hz | |

| Surface Finish | Color Coated | |

| Motor Power | 10 HP |

We manufacture Stainless Steel Reactor from 50 LTR capacity to 50000 LTR capacityEstablished in the year of 2004, Prakash Industries are the leading Manufacturer And Exporter of an extensive array of Industrial Mixer, Grease Plant, Chemical Reactor, Blending Machine And Plant, Reaction Vessel, Storage Vessel Tank, Resin Plant, SS And MS Pilot Machine,Automatic PVA Emulsion Plant, etc.

Product Details:

| Storage Capacity | 1 KL |  |

| Material | Mild Steel | |

| Usage/Application | Industrial | |

| Max Pressure | 0-3 kg | |

| Automation Grade | Manual | |

| Features | Vertical Orientation | |

Product Details:

| Max Temperature | 160 Degree C | |

| Material | Mild Steel | |

| Frequency | 50-60 Hz | |

| Phase | 3 Phase | |

| Power Source | Electric | |

| Surface Treatment | Color Coated | |

| Voltage | 220-380V | |

| Brand | Prakash | |

| Motor Power | 7 HP | |

| Tank Capacity | 2.2 KL | |

| Surface Finish | Color Coated |

Price Range:-

Rs 2 Lakh to 50 Lakh Established in the year of 2004, Prakash Industries are the leading Manufacturer And Exporter of an extensive array of Industrial Mixer, Grease Plant, Chemical Reactor, Blending Machine And Plant, Reaction Vessel, Storage Vessel Tank, Resin Plant, SS And MS Pilot Machine,Automatic PVA Emulsion Plant, etc.

We manufacture Stainless Steel Reactor from 50 LTR capacity to 50000 LTR capacity Established in the year of 2004, Prakash Industries are the leading Manufacturer And Exporter of an extensive array of Industrial Mixer, Grease Plant, Chemical Reactor, Blending Machine And Plant, Reaction Vessel, Storage Vessel Tank, Resin Plant, SS And MS Pilot Machine,Automatic PVA Emulsion Plant, etc.

Product Details:

| Material | Stainless Steel |  |

| Max Pressure | 0-3 kg | |

| Automation Grade | Manual | |

| Features | Vertical Orientation, Horizontal Orientation, Insulated Jacket | |

SS (Stainless Steel) 316 chemical reactor is a vessel used for chemical reactions such as synthesis, polymerization, or decomposition. It is constructed from stainless steel grade 316, which offers high corrosion resistance and durability in corrosive environments.

Stainless steel chemical tanks Heat, acid, and steam: chemical tanks and vessels are subjected to exceptional stresses. Our engineers utilise high-quality stainless steel grades to ensure these vessels withstand a wide range of chemicals, from water treatment operations to the production of cleaning agents.

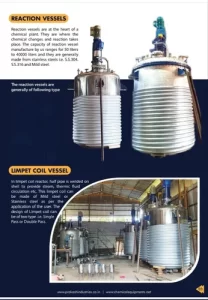

Limpet SS Coil Reactors Limpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

High performance; High durability; Better heat transfer Result; Designed for thermic fluid heating; can handle slurry; energy efficient agitator.

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis.

Stainless steel is the ideal material choice for a wide range of chemical plant applications. Its strength and resistance to corrosion are incomparable. A stainless steel filter and seamless pipe combination is a mainstay of modern fluid systems.

Stainless steel reactors are closed systems where chemical reactions occur, typically under high pressure and temperature conditions. These reactors are essential components of various industries involved in chemical processes.

Limpet SS Coil ReactorsLimpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Limpet SS Coil ReactorsLimpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Limpet SS Coil Reactors Limpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Limpet SS Coil ReactorsLimpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Limpet SS Coil ReactorsLimpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Limpet SS Coil Reactors Limpet reactors are used for high-temperature applications as they give better heat transfer as compared to a jacketed vessel. Usually, limpet coil reactors are used for thermic oil service. Cooling is carried out through an internal coil or through alternate limpets for heating cooling.

Jacketed Reaction Vessel consist of a cylindrical vertical shell with standard tori spherical dish on both ends. During reaction, temperature of reactants is controlled by circulating heating or cooling media through the jacket. Ideally suitable for the heating below 200 Centigrade.

Jacketed Reaction Vessel consist of a cylindrical vertical shell with standard tori spherical dish on both ends. During reaction, temperature of reactants is controlled by circulating heating or cooling media through the jacket. Ideally suitable for the heating below 200 Centigrade.

A jacketed reactor, also known as a double-walled reactor, consists of an inner vessel (core) that holds the chemical reactants and a surrounding outer shell (jacket) that circulates a heating or cooling fluid. The purpose of the jacket is to regulate the temperature of the reaction inside the core vessel.

Jacket Reactor Vessel · Material Grade: SS304 · Max Design Pressure: >40 bar · Usage/Application: Chemical, Water, Oil · Capacity: 100 L · Material: Mild Steel …

Jacketed Reaction Vessel consist of a cylindrical vertical shell with standard tori spherical dish on both ends. During reaction, temperature of reactants is controlled by circulating heating or cooling media through the jacket. Ideally suitable for the heating below 200 Centigrade.

acketed Reaction Vessel consist of a cylindrical vertical shell with standard tori spherical dish on both ends. During reaction, temperature of reactants is controlled by circulating heating or cooling media through the jacket. Ideally suitable for the heating below 200 Centigrade.

Cooling coils are available in the same choice of materials as the reactor bodies themselves. All cooling coils are removable. Plugs are available to close the …

The AAF Nuclear Cooling Coils are for Systems which require temperature control in addition to air filtration and gaseous contaminant removal. Typical applications include emergency and/or normal cooling of Reactor Containment, control rooms, switch gear, pump rooms, and process air.

Cooling coils are proposed that are used in industrial oxidation or ammoxidation reactors that can be made more compact by providing separate sections …

A tank reactor may have a cooling or heating jacket or cooling or heating coils (tubes) wrapped around the outside of its vessel wall to cool down or heat up the contents, while tubular reactors can be designed like heat exchangers if the reaction is strongly exothermic, or like furnaces if the reaction is strongly …